Complete Kit, béton lissé Pro

Order shipped within 7 days

The kit polished concrete Pro includes all the necessary products to make surfaces for 5, 10, 15, 20 and 50 m2, 5 mm thick, with a primary Pro (epoxy resin).

The polished concrete is a coating that has the advantage of being able to ask quick and simple.

Color

Choose from color chart

Packaging

Finishing

Description

Smooth Concrete

Description

Harmony Smooth Concrete is a self-levelling compound made up of cement, selected aggregates, resin and super-plasticizing agents.

It can be used for the rapid finishing of large surface areas, or where only limited shading effects are required.

Harmony Smooth Concrete can be applied from a minimum thickness of 4 mm up to a maximum thickness of 27 mm. It produces a smooth and silky finish, with subtle effects.

Characteristics

Type: Self-levelling mortar

Colours: 15

Particle size: 0 à 2 mm

Packaging: 25 kg bag or tub

Compression strength: 51.85 N/mm2 after 28j

Bending strength: 14.71mpa after 28j

Dosage: 1.7 kg/m2 per mm of thickness, or 3.6m2 for a 4 mm course. Always allow a margin of error, to the amount of one 25 kg bag for the coverage of 3m2 to a depth of 4 mm.

Storage: 12 months in unopened original packaging, stored in a dry and frost-free location.

Guarantee: Manufacturer’s liability

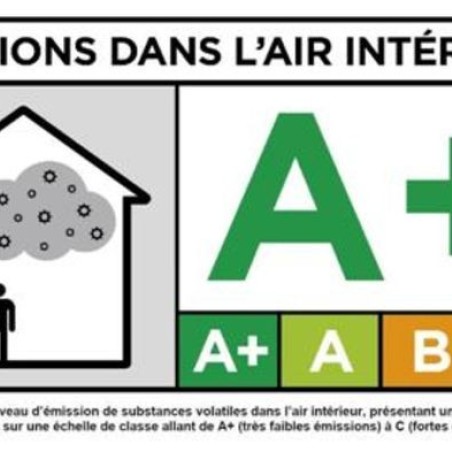

Compliant with standard NF EN 13813

Tools & Cleaning

Mixer, Flemish trowel, gauge rake, studded boots, screen or spiked roller, 40-litre bucket, weighing balance, protective gloves, tarpaulin, adhesive tape. Clean tools in water after use.

Prepare the support

The base surface must be resistant, sound, solid, clean, dry and free of humidity.

Use Harmony neutral agent or Harmony degreaser for any cleaning required (to remove grease, oil etc).

Any existing expansion joints, bay joints and edge joints in screeds or slabs should be observed. Specifically, this is essential in the case of heated floors.

Should it be necessary to level the surface before the application of Harmony Smooth Concrete, use Harmony levelling compound.

Otherwise, you are advised to check the compatibility of levelling with our primers and with Harmony Smooth Concrete.

Regardless of the base surface, whether porous or impervious such as tiling or anhydrite screed, sand- screened Harmony epoxy primer should be applied. (For more information see data sheet epoxy primer).

Internal corners (pillars, right angles, etc.) should be rounded at the base in order to prevent cracking. Door threshold strips should be fitted to allow the interruption of the pouring process.

Do not forget to fit the edging strip, in order to separate walls from the flooring, and protect timber with adhesive tape.

It is essential that exposure to wind and sunlight should be prevented during application and drying. Close shutters or black out windows, and eliminate draughts by applying adhesive tape to the bottom of doors.

In case of application to a heated floor, floor heating should be shut down 48 hours beforehand. Floor heating may be restarted 72 hours after pouring.

Application

Application must be completed within a temperature range of 10° - 25°.

The mix will remain workable for 10 minutes.

For the application of Harmony Smooth Concrete, it is recommended to use a minimum of 3 persons (2 for the preparation of concrete mixtures and 1 for application), if not 4 persons (2 responsible for mixing and dosing, 1 for application and 1 for the acquisition of supplies).

Mix one 25 kg bag with 6 litres of water using a 500 r.p.m. electric mixer to produce a uniform mix by the progressive addition of dry powder to the water.

CAUTION: Harmony Smooth Concrete is sensitive to excess water. Always use the quantity of water recommended. The simplest solution is to weigh the water before each mixing operation.

Mix for a maximum of 3 minutes, then leave the mixture to rest for 1 minute in order to allow the dispersion of bubbles.

In order to eliminate any lumps, use the PermaPro screen to screen the mixture, then transfer to another bucket. Apply Harmony Smooth Concrete in a 4 mm layer using the PermaPro gauge rake.

If the PermaPro screen has not been used, the PermaPro spiked roller should be applied to ensure effective load distribution and the elimination of any lumps. Smooth the surface using the PermaPro Flemish trowel.

CAUTION: Excessive smoothing of the surface will create colour effects. In order to obtain the most uniform finish possible, and to prevent any joints between mixes, pouring operations should proceed in a rapid sequence, and the next bucket in succession should slightly overlap the previous bucket, in order to ensure a uniform surface.

The floor surface will be walkable, preferably in stockinged feet, 6 hours after the end of pouring at an ambient temperature 20°C (at standard humidity).

Depending upon the ambient temperature, 24 – 48 hours after the application of Harmony Smooth Concrete, it will be possible to grind the surface using an eccentric grinder with a 120-grit grade, or using a floor buffer.

Grinding produces a smoother and silkier finish, and enhances textural effects.

Protection

For normal traffic, use Harmony Béton Premium lacquer. For heavy traffic, or for maximum protection, use Harmony pore sealant, then apply Harmony Béton Optimum lacquer.

To protect your lacquer against abrasion, use Harmony Wax.

For more informations see data sheet on laquers and wax.

Epoxy primer

Description

Harmony Epoxy Primer is a two-component liquid epoxy adhesive, activated by mixing.

It is designed for application as a primer on wet base surfaces, such as showers, sinks, washbasins or, more generally, any base surface which is in regular contact with water or humidity, prior to the application of Harmony Waxed Concrete.

Harmony Epoxy Primer must be applied as a primer to tiling or any type of screed, including anhydrite screed, prior to the application of Harmony Smooth Concrete.

Over conventional acrylic primers Harmony Epoxy Primer has the advantage that it prevents rising damp, increases the grip and reduces the risk of blistering.

Characteristics

Type: Two-component resin

Density: A + B: 1,06 ± 0,02

Dry extract: 100%

Flash point: > 100 °C

Packaging: 1kg, 5kg, 25kg

Total weight of 25 kg-Sets: component A: 9 kg, component B: 16 kg,

Total weight of 5 kg-Sets: component A: 1,5 kg, component B: 3,5 kg,

Total weight of 1 kg-Sets: component A: 0.3 kg, component B: 0,7 kg

Dosage: 200g/m2

Drying time: 30 minutes to 2 hours, depending on the type of substrate and the ambient temperature.

Recoatable: At least 24 hours after application.

Storage: 6 months in unopened original packaging, stored in a dry and frost-free location.

Guarantee: Manufacturer’s liability.

Tools & Cleaning

Mixer, roller, protective gloves.

Clean tools with acetone after use.

Prepare the support

The base surface must be resistant, sound, solid, clean, dry and free of humidity.

Use Harmony neutral agent or Harmony degreaser for any cleaning required (to remove grease, oil etc).

On new flooring and/or in building which has yet to be occupied, a minimum waiting time of 36 hours is advised, subject to compliance with the drying time for the foundation slab.

Application for repairing cracks

Open the crack with the help of a diamond grinding wheel. Extract dirt particles with a blower or air compressor. First fill the gap with the epoxy resin primer (make sure that component A and component B are well mixed) and then apply the same mixture with the roller over the surface again.

Let it dry for 48 hours.

Application to prime the surface

The ambient temperature, and the temperature of the base surface, must lie within a range of + 5° to + 30 °.

The mix will remain workable for 15 minutes. It is advised that two people should be available to apply the mix.

If this is not possible, and depending upon the area to be covered, pide component A and component B into a number of batches, then mix progressively as work proceeds.

Example: in the case of a 5 kg kit, pide component A into two batches and component B into two batches.

Pour component B of Harmony Epoxy Primer into component A and mix using a stirrer operating at low speed to form a uniform paste.

Apply Harmony Epoxy Primer to the surface immediately using a roller. For large surface areas, use the 250 or 500 mm PermaPro special floor nozzle.

Screen by the progressive application of Harmony Sand as the application of Harmony Epoxy

Primer proceeds, at a ratio of 25 kg of sand per 10 m2.

In case of application to a base surface which is in regular contact with water or humidity (shower, washbasin, etc.), Harmony Epoxy Primer should be applied to the surface by roller, prior to the application of Harmony Waxed Concrete.

Allow to dry partially, then apply Harmony Waxed Concrete to the still slightly damp surface.

Allow to dry for a minimum of 24 hours before removing the surplus sand.

After vacuuming the sand, it sometimes happens that the sand does not stick in some places.

This phenomenon is due to a lack of epoxy resin during application. Mostly this does not cause any problems as long as these gaps are small / do not exceed the palm of the hand. If there are large areas, you can re-apply epoxy at these locations.

Services

Payment

We guarantee a secure payment by

Delivery

- Shipped within 48 hours After reception of payment. . Period for carriage between 2 and 4 days

- Delivery to the following countries

France, Belgium, Luxembourg, Germany, Austria, Poland. - For Corsica, the DOM/TOM and other destinations in Europe, please contact us so that we can assess the shipping costs

Customer Service

You can contact us

- via chat : at the bottom right

- via telephone : 04 42 20 10 09

from Monday to Friday from 8:00 a.m. to 8:00 p.m. and Saturday from 8:00 a.m. to 6:00 p.m. - via email : At the following address

contact@harmony-beton.com

Features

| Type of room | Bedroom Dining room Kitchen |

|---|---|

| Support current | Tile |

| Particle size | 0 to 2 mm |

| Consumption | 1.7 to 1.8 kg/m2/mm |

| Compression | 51 Npa |

| Bending | 14 Npa |

| Cleaning | Water |

| Compliant | NF EN 13813 |

| Conservation | 12 months in its unopened packaging and stored in a dry, frost-free place |

| Warranty | RC manufacturer |

| Project | Ground |

Product instructions

Reviews

Related products

You may like

Kit polished concrete screed anhydrite

Complete patinated concrete kit